Lockjaw 2 Slider System

$360.00

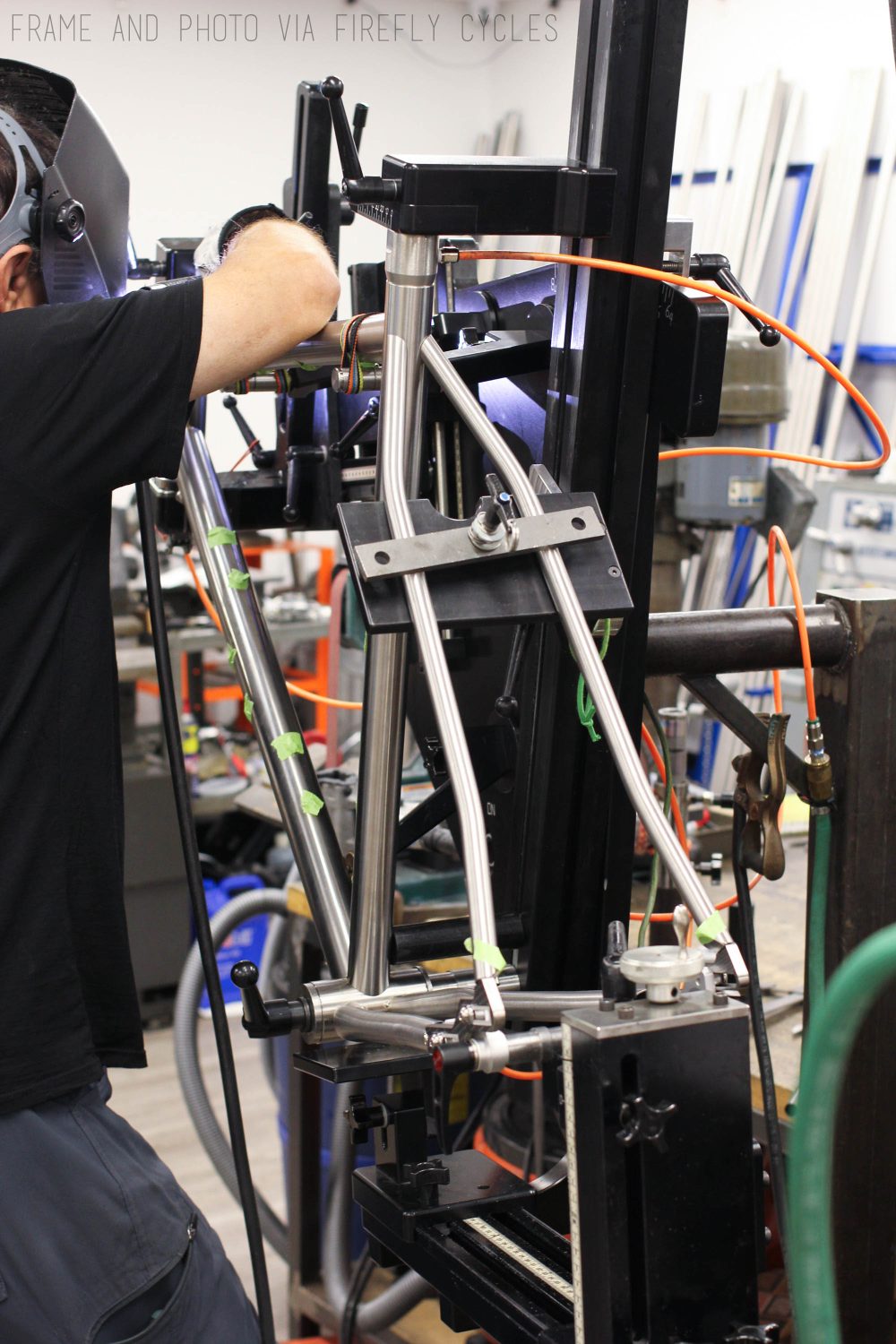

For the launch of our Flaanimal 6 Titanium and TD4.2 framesets, we developed an entirely new sliding dropout system from the ground up. The Lockjaw 2 sliding dropout system is an elegant and modern solution for not just our bikes, but now also for other small batch frame builders who want to build frames with their customers with Lockjaw 2 versatility in mind. After over a year in the wild on our bikes, we are now making our slider system available to other builders as a friendly gesture to the larger cycling community that we are a part of. Our system is available with both both steel and titanium frame compatibility. Eevery part, including the system’s titanium M30 fastening bolts, is 100% CNC machined, bespoke, directly for our design. We require that every builder who orders these sliders agree to and sign our Lockjaw 2 use agreement before we will fill any order. The Lockjaw 2 design is the product of years of dedicated work, and we’re keen to protect it. All orders will be reviewed before shipping. Lockjaw 2 is not being made available to serial-production bike companies. It is only offered to low volume / small batch frame builders that we consider peers, friends, or collaborators in the industry.

Lockjaw 2 Overview

A chief motivator in all Rodeo Labs product design is versatility. How can we give the owners and riders of our bikes and products to most possible function and compatibility with any given product that we sell? Lockjaw 2 was created to extend that thinking into the dropout area of the bikes that we ourselves create and build, and now we’re inviting other builders to build with that same function and flexibility for their own customers.

Each Lockjaw 2 kit includes:

- Drive-side UDH slider (7075 aluminum)

- QTY 4 Titanium M30 x 6mm slider bolts

- QTY 4 7075 aluminum lockjaw slider plates.

- Through axle not included, but can be ordered here

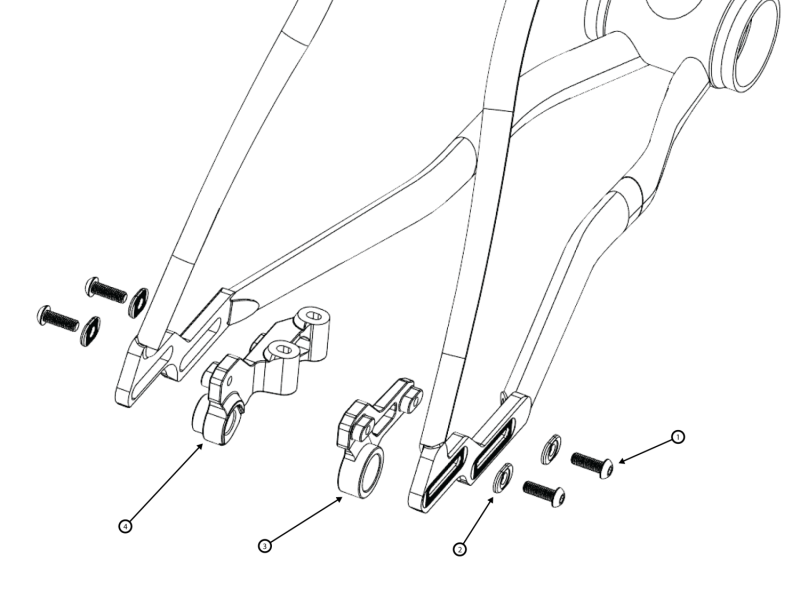

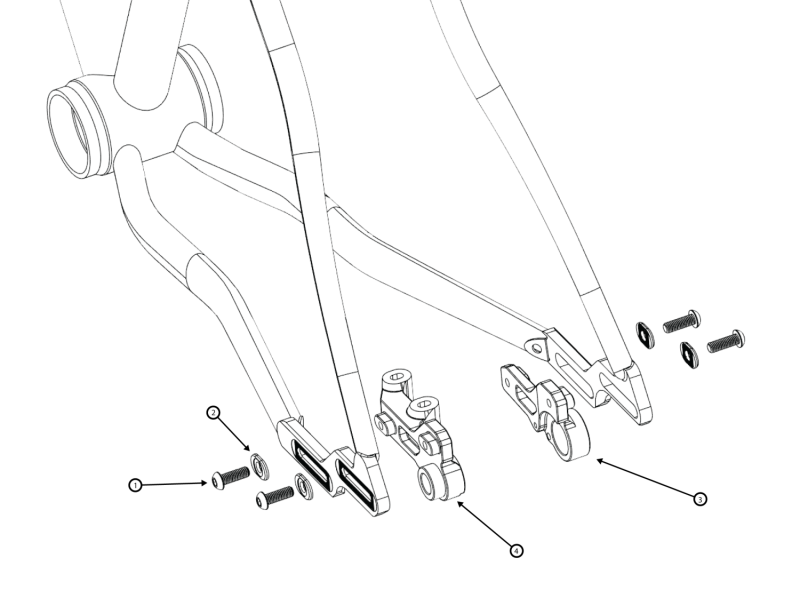

System Diagram

- 160mm native flat mount disc brake caliper mount, compatible with standard hydro caliper and large calipers such as those from Paul, Growtac, or TRP

- Strong titanium sawtooth profiles CNC machined into the frame

- Four corresponding custom CNC’d Stainless Steel Sawtooth Compression Plates (2)

- Four M6x14mm Titanium Fixing Bolts (1) (Use 11nm of torque on each bolt)

- The aluminum sliding dropouts, non-driveside (brake mount, 4) and driveside (derailleur mount, 3)

- The rear thru-axle and accompanying Clever Lever axle tool

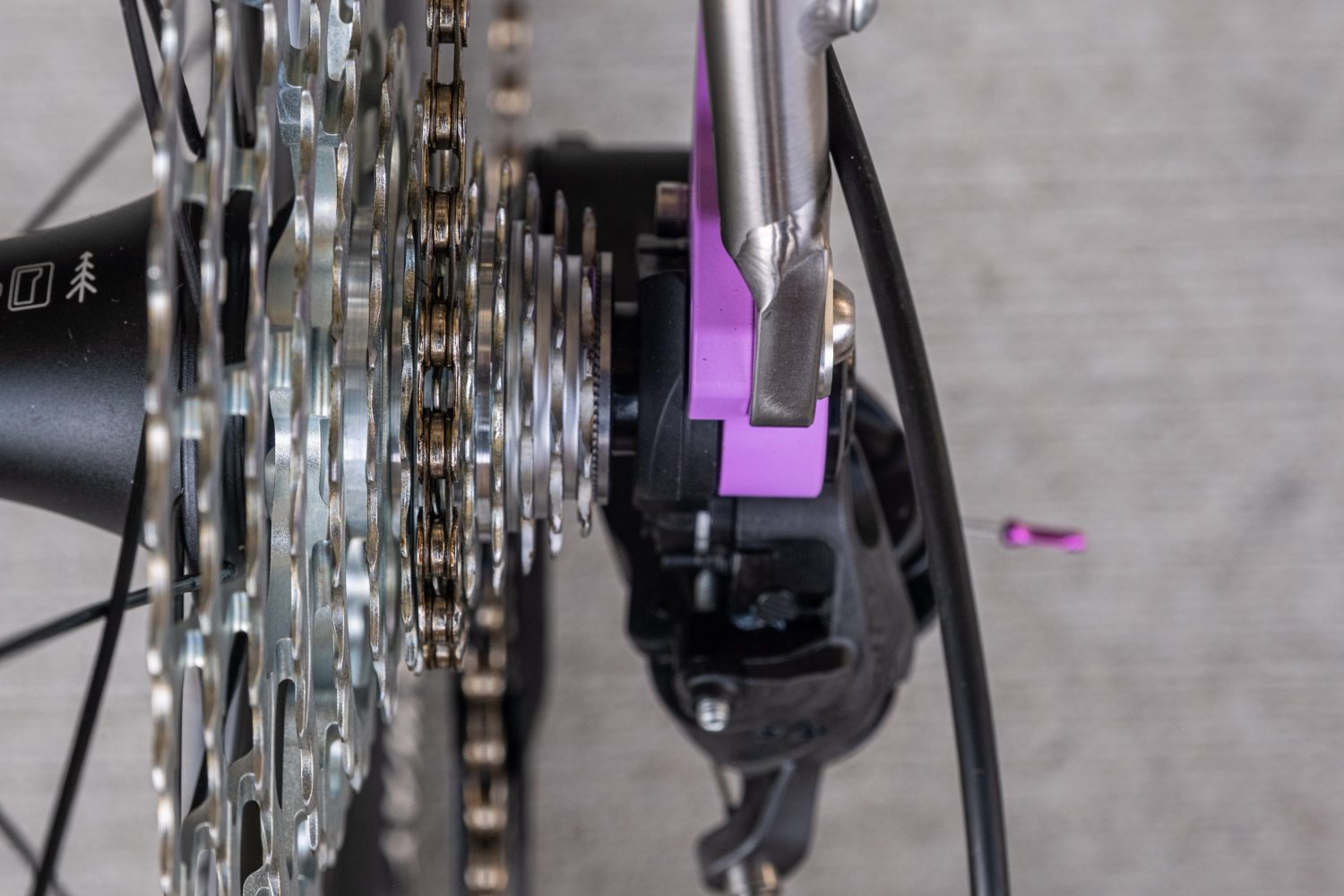

Our slider system is now SRAM T-Type Direct Mount native. You may install a SRAM UDH Hanger in the event you are running a non-T-Type derailleur, which is offered as a convenient add-on at checkout.

The easiest and most effective way to set up your sawtooth slider system is in this order:

- Place the non-driveside slider (4) into the frame slot from the inside.

- Tighten both bolts to your approximate needed rear wheel location by mocking up with the wheel.

- Set up the driveside slider (3) loosely, then thread in the rear axle.

- Make sure the driveside is loose enough to be pulled into alignment with the brakeside slider when tightening the axle.

- When the loose slider finds its corresponding parallel location to the tightened non-driveside, you can now tighten the driveside fixing bolts.

- Fine tuning this system in the event you find it is not perfectly aligned after this procedure involves simply moving one slider forward or backward in the appropriate direction to match the other slider side.

- When using a singlespeed setup, it is at this point you can cut the chain to the approximate size. If you have tucked the tire toward the frame, cut the chain on the long side and reposition the sliders equally backward on the sawteeth to achieve proper chain tension. If you have adequate forward tire clearance, you are free to cut the chain either too short or too long and adjust tension using the sawteeth in equal increments on each side. If you placed the sliders all the way back, cut the chain on the short side and then move the sliders forward until the chain can properly wrap on the cog. For the cleanest singlespeed look, we recommend machining the derailleur hanger off of the UDH derailleur hanger, as pictured in the product gallery above. (We do not sell the UDH derailleur hanger).

For techincal assistance with integrating the Lockjaw 2 design into your frame, please reach out to us at bikes@rodeo-labs.com

Component Weights

Titanium dropout – 70g/side

Steel dropout – 121g/side

NDSslider – 74g

DS slider – 35g

Bolts – 9g

Washers – 10g